Congratulations and a New Year gift to Bruce Peng! This is a great example that motivated undergraduate student can lead an important project and publish a great paper in Wang Group!

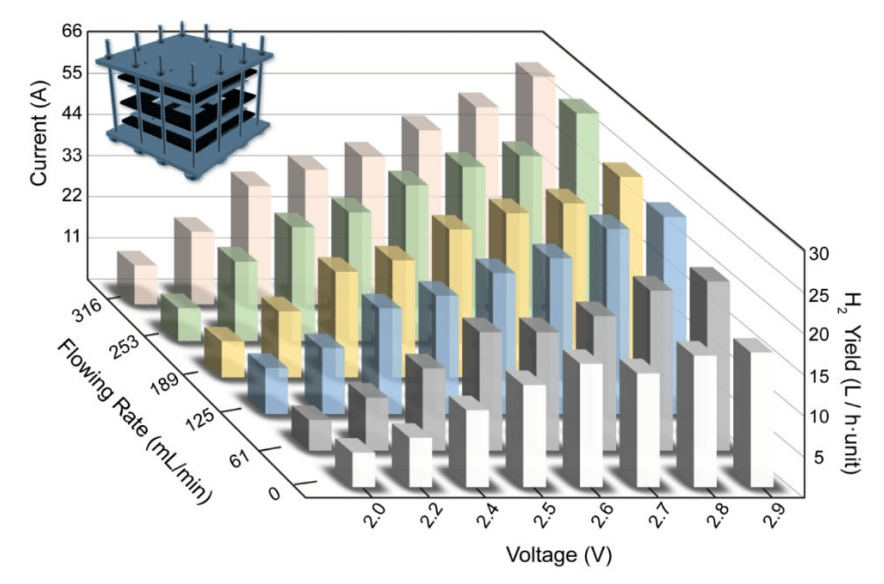

Scaling up electrochemical water splitting is nowadays highly demanded for hydrogen economy implementation. Tremendous efforts over the past decade have been focused on exploring alternative catalytic materials, including a variety of earth-abundant transition metal based catalysts, to replace traditional noble metals such as Pt, Ir or Ru. Nevertheless, few efforts have been carried out for 1) scalable catalyst synthesis on current collectors, and 2) practical device design toward large-scale H2 generation. Herein, we designed a modular alkaline water-splitting electrolyzer system with scaled-up metal foam electrodes covered by low-cost NiMo alloy and Ni3Fe oxide for efficient hydrogen evolution and oxygen evolution, respectively. An electrolyte circulation system facilitates the mass transport and thus can further boost the H2 generation particularly under large currents. As a result, the overall water-splitting performance of one-unit cell with a dimension of 10X10 cm2 under room temperature presents an early onset voltage of 1.54 V, and delivered practical currents of 20 and 55 A (9.1 and 25.0 L/h H2 generation) under 2.2 and 2.9 V without iR compensations, respectively. This demonstration could stimulate new focuses in water-splitting towards more practical applications.